In particular, private sector analysts have recognized the connection between the growth in construction for electronics manufacturing and the CHIPS Act. The Semiconductor Industry Association reports that over 50 new semiconductor ecosystem projects have been announced in the wake of the CHIPS Act. Construction costs have risen quickly in recent years, and therefore nominal spending growth should not be misconstrued as increased physical construction. But by considering deflated measures as we do here, it is clear that the surge is a real one (see Appendix for a more detailed discussion of our https://x.com/bookstimeinc choice of deflator). Cross-functional teams are formed to lead and facilitate the TPM implementation. These teams usually consist of members from different departments, such as maintenance, production, quality control, and even finance and human resources.

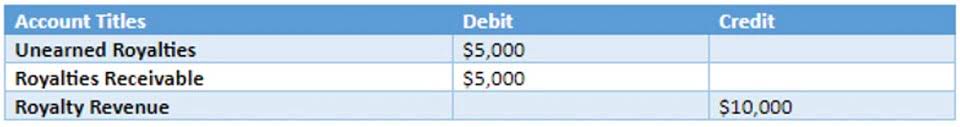

- It directly affects profit margins and is crucial for financial reporting and tax calculations.

- Cross-functional teams are formed to lead and facilitate the TPM implementation.

- The price index for gross domestic purchases increased 1.8 percent in the third quarter, compared with an increase of 2.4 percent in the second quarter (table 4).

- TPM’s effectiveness lies in its ability to bring together diverse workforce elements, fostering a shared responsibility for equipment care and performance optimization.

Total Manufacturing Cost

These contributions have shaped TQM into a disciplined strategy for continuous improvement in processes, products, and services, aiming primarily at enhancing customer satisfaction. The Pillar of Quality Maintenance aims to eliminate defects within products by maintaining equipment in optimum condition. This involves integrating principles of total quality management (TQM) into maintenance activities and focusing on understanding the connection normal balance between equipment conditions and product quality.

Step Two – Restore Equipment to Prime Operating Condition

In 2023, it had an estimated 9,905 manufacturing jobs, up more than 4,100 since 2019. After adding 21,000 jobs from 2015 to 2019, employment in the industry has since fallen by 46,000. In nearly half of the country’s states — and fully half of all counties — manufacturing employment has not yet rebounded to 2019 levels. The manufacturing recovery has not reached, for example, the so-called “Rust Belt” states of Pennsylvania, Ohio, Indiana, Illinois, Michigan and Wisconsin. Finally, we explore international data and find that the same total manufacturing cost formula surge in manufacturing construction is not apparent in other advanced economies.

Change in manufacturing jobs by county type, 2015-19 and 2019-23

Moreover, such an expense is a crucial factor in determining the sales price of goods. Therefore, it is critical for cost management in manufacturing companies where minimizing the factory overheads results in higher profits, ensuring overall operational efficiency. The price index for gross domestic purchases increased 1.8 percent in the third quarter, compared with an increase of 2.4 percent in the second quarter (table 4). The personal consumption expenditures (PCE) price index increased 1.5 percent, compared with an increase of 2.5 percent.

- With our extensive inventory of parts along with repair and machine shop services and plant maintenance solutions, TMS is the complete source for all your electrical and mechanical power transmission needs.

- By using the total manufacturing cost formula, you can monitor material, labor, and overhead costs effectively.

- This helps in understanding production expenses and managing budgets effectively.

- These pillars are designed to work together to improve the overall effectiveness and efficiency of production processes.

- Cost of goods sold (COGS) pertains to the cost of inventory that was actually sold during a specific period, influenced by both the COGM and the changes in finished goods inventory.

- While manufacturing jobs have surpassed pre-pandemic levels nationally, this growth is highly concentrated geographically.

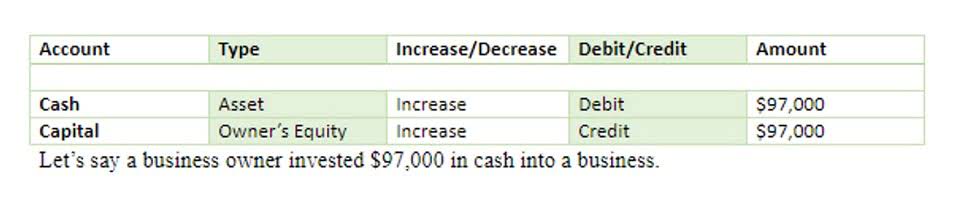

It is computed by dividing the total manufacturing cost in a given period by the total number of units of a particular commodity produced in that period. If the company produces 5000 bags quarterly, determine the total manufacturing cost per unit. Effective cost management systems help control expenses, improve efficiency, and boost profitability. Integrating these systems with other business tools ensures smooth operations and better decision-making. Percent changes in quarterly seasonally adjusted series are displayed at annual rates, unless otherwise specified. Real gross domestic product (GDP) increased at an annual rate of 2.8 percent in the third quarter of 2024 (table 1), according to the “advance” estimate released by the U.S.

- The legislation increased the available Private Activity Bonds (PABs) authority from $15 to $30 billion.

- This metric provides a comprehensive view of the production expenses incurred by a company.

- To ensure the success of TPM training at all levels, it should be implemented to create awareness, stakeholder engagement, and successful implementation.

- Marvin Goldman and Kevin Orlofski, both power transmission specialists with over 60 years of combined experience have created the ideal single source distribution company to meet the needs of local manufacturers.

- Each pillar addresses a specific area of maintenance and improvement within the business.